With the world at a virtual standstill, auditing supply chains has become a near impossible task. Travel restrictions will limit the movement of people for some time to come and the safety of on-site auditors in the face of the coronavirus pandemic should remain a serious concern. Companies, therefore, have to weigh alternatives to audits as they still need the necessary assurances that suppliers are compliant with their sustainable procurement requirements.

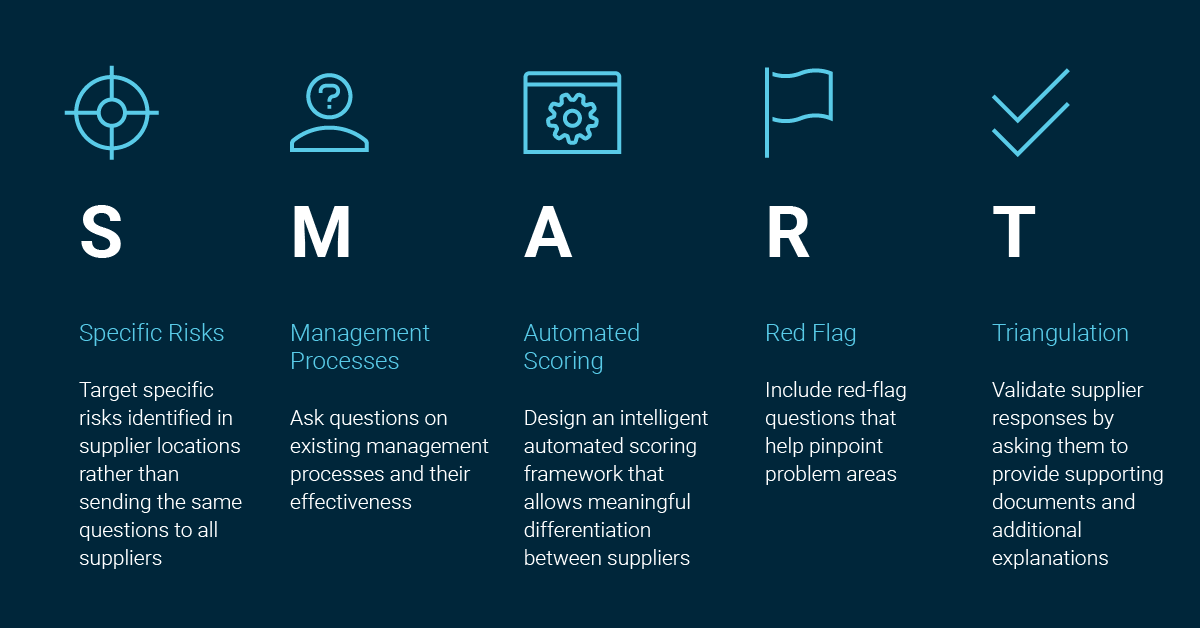

One of the best options is the self-assessment questionnaire (SAQ). But not any old SAQ will work. To bridge the gap to on-site audits we have designed a new approach – the SMART SAQ – which can be an effective replacement tool in supplier management.

We’ve developed the SMART SAQ to follow a set of principles that will help companies through the unprecedented challenges facing them in these times and which could shape the way they target their audits once we come out the other side.

Overview of SMART SAQ Principles

- S – Specific Risks

Supplier management systems often involve some sort of initial risk assessment to identify potential hotspots and prioritise follow-up actions. In case of SAQs, once a pool of suppliers with a higher risk exposure is identified, all of them tend to receive very similar (and often very lengthy) questionnaires.

SAQ effectiveness could be increased – and the burden on suppliers could be relieved – if SAQs target specific risk areas for each supplier. For instance, if a risk assessment establishes that a supplier operates in a country with almost no child labour, but a high risk of modern slavery, there is little benefit in asking this supplier whether it has a child labour policy. By contrast, we do want to find out what policies and procedures are in place to protect its workers and sub-suppliers from labour exploitation.

- M – Management Processes

Asking about and verifying the existence of policies is easy. That’s why many SAQs tend to focus on this aspect of supplier management systems. However, simply having a policy is no guarantee that there are effective systems in place to implement it. In order to increase the trustworthiness of SAQs, it is essential to ask questions about management processes and their outcomes. In terms of occupational health and safety (OHS) for example, we need to know if a supplier has procedures to record and investigate accidents and incidents and what the actual number for these are; whether it has fire exits and evacuation procedures; or if employees are issued with personal protective equipment (PPE).

- A – Automated Scoring

The lengthier the questionnaire the more time is required to manually analyse supplier responses, especially if SAQs are rolled out extensively. Instead, an intelligent automated scoring system could help analyse responses efficiently and identify truly high-risk suppliers. This scoring framework should be more complex than simply saying that all ‘Yes’ answers will get 1 point, all ‘No’ answers will get 0 points. A scoring methodology of this kind will likely result in all suppliers looking very much the same. Questionnaire designers should instead think about each question’s importance in driving the overall score (i.e. expressed in terms of the number of points given to a question or a question weighting).

- R – Red Flags

Red flag questions can also help with supplier differentiation. For example, if a supplier has an anti-bribery and corruption (ABC) policy but the only corruption examples that it gives are bribes and excessive gifts, there is a risk of overlooking other forms of corruption, such as facilitation payments or those resulting from conflicts of interest. This is a red flag for the integrity of supplier’s ABC system, which should be captured in the SAQ through a significant negative score, high weighting, or a ‘rule’ that would allow the poor answer to this question to overwrite all positive scores gained for other questions in the ABC section.

- T – Triangulation

Finally, to increase the trustworthiness of SAQs, it is important to make sure that supplier responses get triangulated, or, in other words, see that they are validated by comparing different pieces of evidence. Requesting supporting documents and asking ‘Why’ and ‘Why not’ questions could be one way of achieving this. Supplier answers could also be externally tested by conducting media analysis. While some of these strategies may require manual work from the procurement team, technological solutions also exist to simplify this task.

Building a framework for the future

While not a complete substitute for on-site audits, the SMART SAQ methodology can greatly assist companies during these testing times. In-fact, once the world gets back to some form of normality, SMART SAQs, used correctly, could replace a percentage of company’s current audit plans and protocols. The utility of SMART SAQs is also not just confined to sustainable procurement. They could extend to safety, quality and/or performance-based exercises, as the methodology is very similar and transferable.

We have extensive experience in helping businesses design and implement SMART SAQ solutions, either in partnership with other service providers (such as SupplyShift) or by building them into our clients’ existing supplier management systems. What this has shown us is that it may not be possible, or even necessary, to implement every aspect of the SMART SAQ framework. But even if only one or two of these recommendations are integrated, the effectiveness and trustworthiness of SAQ responses increase dramatically.